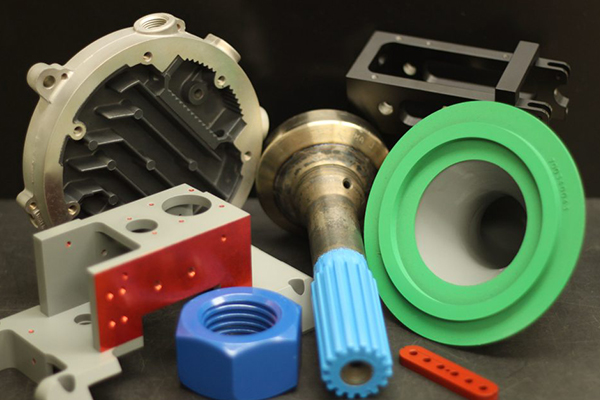

Services

Coating Services

Pretreatment Capabilities

At Crest Coating, we know the key to a good finish is the surface preparation. Abrasive blasting is the best way to remove rust and oxidation, and at the same time provide a good surface on which coating can adhere.

BCS Bakeware Coatings

Crest Coating is one of two firms licensed to apply BCS Coatings in the U.S. For years commercial bakeries have had to rely on pan coatings that do not provide the release or longevity needed for optimal productivity. BCS Coating Technologies were specifically developed to address the stringent requirements of commercial bakeries. These coatings are, by far, the longest lasting available today, and they provide the best release for baked products. Crest Coating is uniquely positioned to provide this superior product to bakeries in the Western U.S.

Chemours Teflon™ Coatings

Chemours recognized the importance in the application procedure and expertise to engineer the appropriate coating system for their Teflon coating products to perform optimally. To accomplish this they created their Licensed Industrial Applicator (LIA) program that includes approximately 20 coaters nationally. Crest has the distinction of being an LIA for more than 40 years.

Because of our experience in applying Chemours Teflon™ coatings, our skilled staff, and modern equipment, Crest has been a Chemours Licensed Industrial Applicator for more than 40 years. This is a source of pride for us, and a source of confidence for our customers.

The variety of Chemours Teflon™ industrial coatings is extensive.

Fastener Coatings

Crest Coating Inc. is a leading industrial coating applicator with over 40 years experience and is known throughout the industry for excellent quality, innovation and service. Put our problem solving technical expertise to work for you. We will provide the best solution for your fastener coating needs.

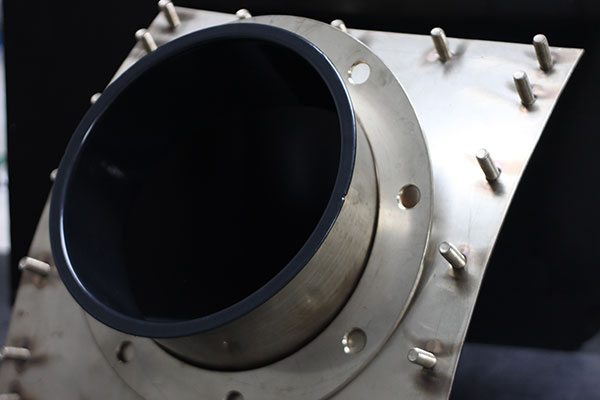

Halar® & Chemical Resistant Coatings

HALAR® is essentially a 1:1 alternating copolymer of ethylene and chlorotrifluoro-ethylene (ECTFE). By weight, it contains about 80% ECTFE, one of the most chemically resistant materials that can be used to make a polymer. Though ECTFE homopolymers are excellent materials, they are difficult to fabricate into complex shapes. By copolymerizing ECTFE with ethylene, HALAR® combines the chemical resistance of ECTFE-based materials with easy processability.

High Temperature Coatings

Crest Coating has been applying ceramic coatings for over 50 years.

Our experience and state of the art equipment will ensure that your coating turns out the highest quality. With our in-house lab we routinely test the various coatings available in the marketplace, and are well equipped to customize a solution that will meet your needs.

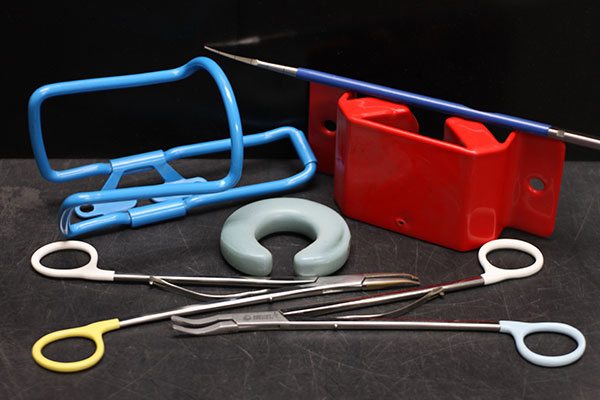

Nylon Coatings

When a protective coating is your first objective, make Nylon your first choice. Nylon combines thermal stability, physical durability, chemical resistance and mechanical integrity into a coating material that stands up to almost anything. Nylon powders are virtually impervious to extremes of pressure, PH, and temperature. Nylon has high dimensional stability, good resistance to stress cracking, and low moisture absorption. Nylon also has a low coefficient of friction and excellent abrasion resistance. Nylon is a green product made from a renewable raw material, namely castor seeds – Castor oil.

PFA® Coatings

PFA® offers the high temp properties and performance of PTFE® (Teflon™) in a thermoplastic. This unique balance of properties combined with the capability of uniformly coating complex shapes with thin or thick films offers the ultimate in fluorocarbon coatings. PFA® comes in industrial and food compatible grades. PFA® offers the same excellent combination of physical properties unique to PTFE coating.

Powder Coatings

Our various conveyorized lines permit us to efficiently process large production runs, as well as smaller custom runs. Crest uses no shortcuts, which results in a reject rate of less than 1 percent. Customers with “just in time” purchasing rely on us to provide the quality services they want, in the quantities they need, on the schedule that they specify.

Mil-Spec Coatings

At Crest Coating, we are a CARC Approved Applicator and have experience in the US Military Powder Coating market. As a Tiger Drylac 5 Star program member, our business has access to exclusive CARC products and services and is annually inspected by the TIGER AFS team.

Specialty Coatings

Today there is a large array of powder coating solutions. We bring our long history of experience and expertise to help you find the option that will best meet your specific needs.

PPG Xylan® Coatings

PPG (formally Whitford) recognizes the importance of a properly engineered and applied coating system. A “Quality Approved Coater” program was established to provide industry competent sources to apply their products. Crest Coating is a charter member in this distinguished network of Xylan coating experts.

PPG Xylan® Coatings have a broad range of properties which make them ideal for a variety of applications. PPG Xylan® Coatings differ from traditional fluoropolymer coatings in one very important aspect they are composite materials. Lubricants with the lowest-known coefficient of friction are combined with the newest high temperature resistant organic polymers to create PPG Xylan® Coatings.