CCI News Crest Coating Inc. Blog

The Evolution of Teflon Coating Technology

Teflon coatings have become a cornerstone in industrial manufacturing thanks to their exceptional non-stick, chemical-resistant, and heat-tolerant properties. What began as a scientific accident in the 20th century is now a critical…

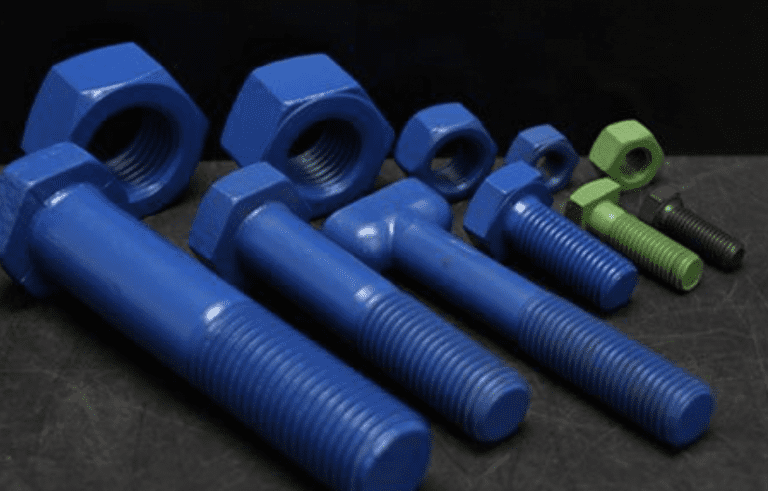

Read ArticleHow to Coat Nuts & Bolts & Other Fasteners Correctly

What you need to know about breakout torque and salt-spray testing. Fasteners that are coated for heavy industry tend to be coated for a very good reason. That’s because the environments where…

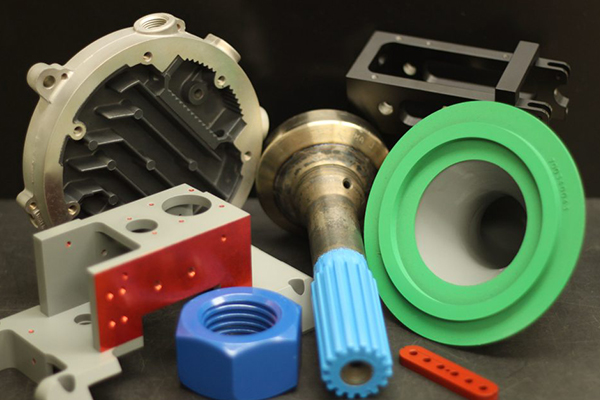

Read ArticlePTFE Coating Services: What You Need to Know

Seamless Solution for Your Specified Application PTFE coatings – What are they? PTFE coatings (Polytetrafluoroethylene) also known as the brand name Teflon are non-stick, fluoropolymer, high temperature coatings. They have either a…

Read ArticleIs Powder Coating Heat Resistant?

Powder coating’s durability and affordability have made our high temperature powder coating a favorite amongst our clients. With its ability to adhere strongly to most metals, it is a great option to…

Read ArticleEverything You Need to Know About PPG Xylan Coating

Xylan is a registered brand name for a type of fluoropolymer coating. Developed, trademarked, and marketed by the Whitford Worldwide Company (which PPG acquired in 2019), Whitford Xylan Coating (now PPG Xylan…

Read ArticleHow Temperature and Humidity Affect the Powder Coating Process

Powder coating is a popular finishing technique known for its durability, efficiency, and eco-friendliness. However, the quality of a powder-coated finish is about more than just the coating itself. It’s also about…

Read ArticleHow Powder Coating Contributes to Product Longevity

The longevity of metal products, from outdoor furniture to heavy machinery and automotive components, is often due to powder coating. This industrial process creates a durable, weather-resistant finish that protects against any…

Read ArticlePowder Coating vs. Liquid Painting: A Comprehensive Comparison

When it comes to surface finishing, two popular methods are often considered: powder coating and liquid painting. Both options offer their own set of benefits and drawbacks, making them ideal for various…

Read ArticleThe Role of Powder Coating in Aerospace Applications

The aerospace industry operates in a demanding environment, where components are consistently exposed to extreme conditions. From high temperatures and harsh chemicals to constant wear and tear, the materials used in aircraft…

Read ArticlePFA Coating in the Food Industry: Safety and Efficiency

Innovations in the materials used across the food processing and commercial baking sectors are pivotal in ensuring safety, efficiency, and quality. Among the most notable advancements, Polytetrafluoroethylene (PFA) has become synonymous with…

Read ArticleExciting Times at Crest Coating – We’ve Just Revolutionized the Coating Process

It’s a very exciting time at Crest Coating HQ at the moment, as our new and improved coating system is now fully operational. Moreover, it promises to be an exciting time for…

Read Article