Bakeries Find New Benefits from Non-Stick Bakeware Coatings

Dough troughs use much less oil, and bun pans can be recoated for extended life.

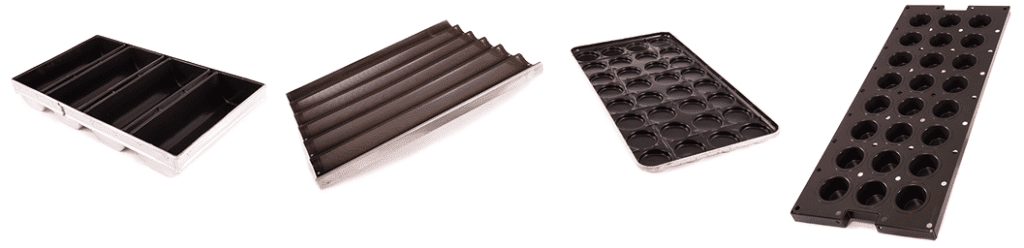

Moving a 400-pound blob of bread dough around the plant floor of a commercial bakery doesn’t sound like an easy task. That’s because it isn’t. A commercial bakery might fill a 12-foot-long trough with bread dough so that it can rise for four hours in a warm, humid room. As the dough rises, it becomes wet, spongy, and sticky.

So, before the bakers fill the trough, they spray the entire surface with vegetable oil so that the dough will slide out when it’s done rising. Some bakeries spend hundreds of thousands of dollars a year on oil alone to complete this process. So much oil can also cause safety issues for employees on the plant floor.

With a DoughGlyde coating applied to these troughs, not only does the dough slide out easily, the trough requires very little oil to aid in the process. And on top of that, trough cleaning time can be greatly reduced because all that’s required is spraying with water. In one case, using the DoughGlyde coating reduced trough cleanup from hours to mere minutes.

Coating loaf and bun pans

Commercial bakeries can use thousands of pans at one time. A common bakeware coating to help baked product release completely and consistently is a silicone glaze. The problem is, the silicone glaze deteriorates slowly, and usually only lasts 250 to 400 cycles. What’s more, as the glaze wears off, the bakers have to adjust their process to keep the pans releasing properly and the line running smoothly.

With a BCS-Teflon application process perfected by Bakeware Coating Systems, bakers can achieve 3,000 to 5,000 cycles before recoating is needed. Because BCS-Teflon coatings are, of course, more expensive per pan than silicone glazing, it takes a little effort to calculate the cost/benefit analysis over thousands of cycles on thousands of pans.

But with commercial bakeries, many see a return on investment in under one year. BCS Bakeware Technologies and BCS-Teflon coatings revolutionized the worldwide commercial bakeware industry, and Crest Coating is one of two coaters nationwide with exclusive rights to coat pans under Bakeware Coating Systems. The additional benefits of BCS-Teflon are that it can be reapplied onto the pans for thousands of more cycles from each application, and during the useful life of each coating application, the release properties remain consistent.