Blog

Architectural and AAMA Rated Powder Coatings

Not All Powder Coats Are Created Equal High-quality powder coating is essential to improving the functionality, appearance, and lifespan of architectural structures like doors, windows, railings, and other essentials. Not all powder coats are created equal, so it is easy to understand why the coating used on your home patio furniture is not the same…

Read BlogMil-Spec: Military Specification Chemical Agent Resistant Coatings

Chemical Agent Resistant Coatings, also known as CARCs, play an integral role in our nation’s defense due to their unique properties. These coatings protect equipment and personnel from radioactive, biological, and chemical threats. At Crest Coating, we are proud of our status as a Mil-spec Approved Applicator through the TIGER Drylac 5 Star Applicator program. …

Read BlogWhy ISO Certification Matters

When it comes to professional coatings, there is little to no margin for error. A slight variation in coating thickness of one-thousandth of an inch (.001”) could lead to the whole project needing to be stripped down and coated again or, in the worst case, scrapped. That’s why ISO certification matters so much. Because when it…

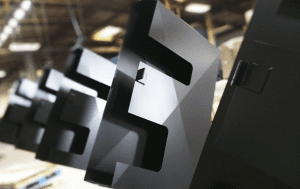

Read BlogRobotic Spraying Systems for Coatings

Here at Crest Coating, our highest priority is providing consistent quality and exceeding our customers’ most demanding requirements. In our decades of operation, we have worked hard to stay at the forefront of the newest technologies and tools to achieve that goal. To that end, our newest investment is a customized 6-axis robotic spraying system.…

Read BlogIs Powder Coating Heat Resistant?

Powder coating’s durability and affordability have made our high temperature powder coating a favorite amongst our clients. With its ability to adhere strongly to most metals, it is a great option to consider for your upcoming project. And, if you’re wondering whether or not it’s heat resistant, the short answer is, “yes”. The long answer…

Read BlogWhen to Choose Nylon Powder Coating

When it comes to the powder coatings we provide, every one of our clients has unique needs that must be addressed. This means that our team meticulously researches the constraints of each project and finds a solution that best meets its requirements. Often, this solution is the versatile nylon powder coating. Typically applied as a…

Read BlogAbout Xylan Coatings: Series Numbers and Properties

Find the properties that match up to your needs. Xylan coatings offer a wide range of properties that create a heat-resistant, highly impermeable, low-friction surface. Because of these features, Xylan coatings are often used as dry-film lubricants, for mold release, on automotive components, for the bakeware industry, and in a range of other industrial applications.…

Read BlogQuality Checklist for Industrial Coatings

Quality is of the utmost importance when it comes to industrial coatings. Crest Coating specializes in industrial powder, Teflon, and liquid coatings. Our highest priority is consistent quality and exceeding our customers’ most demanding requirements. Meeting this goal requires the latest in inspection and quality assurance equipment. Below is a checklist of the tools and measures…

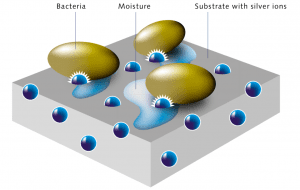

Read BlogHow Do Antimicrobial Coatings Work?

Additives such as silver ions inhibit germ growth.

Read BlogThe Key Factors When Quoting Coating Jobs

Asking the right questions quickly narrows down the options.

Read Blog